What about the customer experience?

18 November 2015 by Catherine Holdsworth in Business and finance, Implementing ISO 9001:2015

Susannah Clarke, co-author of Implementing ISO 9001:2015, asks whether the principles of DFMA are enough if customer delight gets overlooked along the way.

I’m working on an interesting project in the construction sector at the moment, looking at how and what this sector can learn from the automotive and aerospace industry and the standards they now achieve, particularly related to Design for Manufacture and Assembly (DFMA).

One area of interest is offsite construction, where modules are designed and built offsite and then transported to the site. The theory is that this approach will drive standardisation, lower costs and reduce the time to build/construct. Of course achieving these goals depends much on the original design being robust and appropriate for offsite construction – it’s got to fit together seamlessly on arrival with the other components.

The importance of this was brought home to me a couple of weeks ago when I received a new desk for my home office. I had ordered it from a store for whom I feel a strong loyalty – many people do; it’s that kind of place. Therefore I had certain expectations: it would be high quality; it would look good; it would meet my needs with drawers, good access and easy sitting position, space to spread my work out on; it would arrive assembled. This is not a flat-pack store, so I was initially quite taken aback when the charming delivery men brought a very flat set of boxes into my house. I was not delighted!

However, undeterred, I set about with my toolbox, the instructions and a willing helper.

I’m going to spare you the photos of me, head in hands and manically waving my screwdriver about.

I’m not even going to talk you through the one afternoon and three evenings that it took me to get the desk completely assembled, although if you want a laugh and a good idea of the challenges I faced, watch the video below of Stephen Fry tackling flat pack furniture assembly (warning: there is some ‘choice’ language!).

I’m going to focus, instead, on what I learned, since it provides valuable insights for suppliers in terms of maximising customer delight.

- Set clear expectations – if you are supplying something which is not assembled, the customer needs to know.

- Instructions are great when they’re pictures, but not when they are too small. I was given an A5 booklet and the pictures were half A5.

- Components need clear labelling so that the customer can identify them easily, particularly when some items are very similar. I was struggling to tell a side panel from a back panel.

- All nuts/bolts/screws/fixings need not only to be itemised but linking them to a component part also helps the customer. I regularly found myself asking, “Is this the right screw for the drawer or is it meant to connect the legs?”

- Reduce the number of parts to make it simple for the customer. I had more desk pieces, drawer parts, handles, drawer runners, side panels, modesty panels and legs than I knew what to do with and enough fixings to open a local hardware store!

Whoever plans the components, needs to mistake-proof it for the customer (assembler). I spent many hours trying to align the drawer runners with the pre-punched holes in the pedestal sides, unable to work out which hole was meant to match which. It was almost impossible.

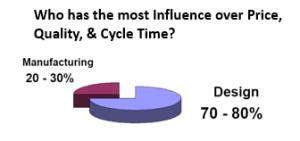

I’m assuming that the manufacturer was able to use the DFM principles. Each part individually looked fairly simple and therefore, one had a sense that it could be mass produced easily. But how did my desk compare to the principles of DFA?

True, the store had removed any costs it would have incurred by assembling the desk itself, and was able to pass these savings on to me, the customer. But, false, it had not minimised the number of assembly operations; in fact it had a vast number of steps, components and fixings.

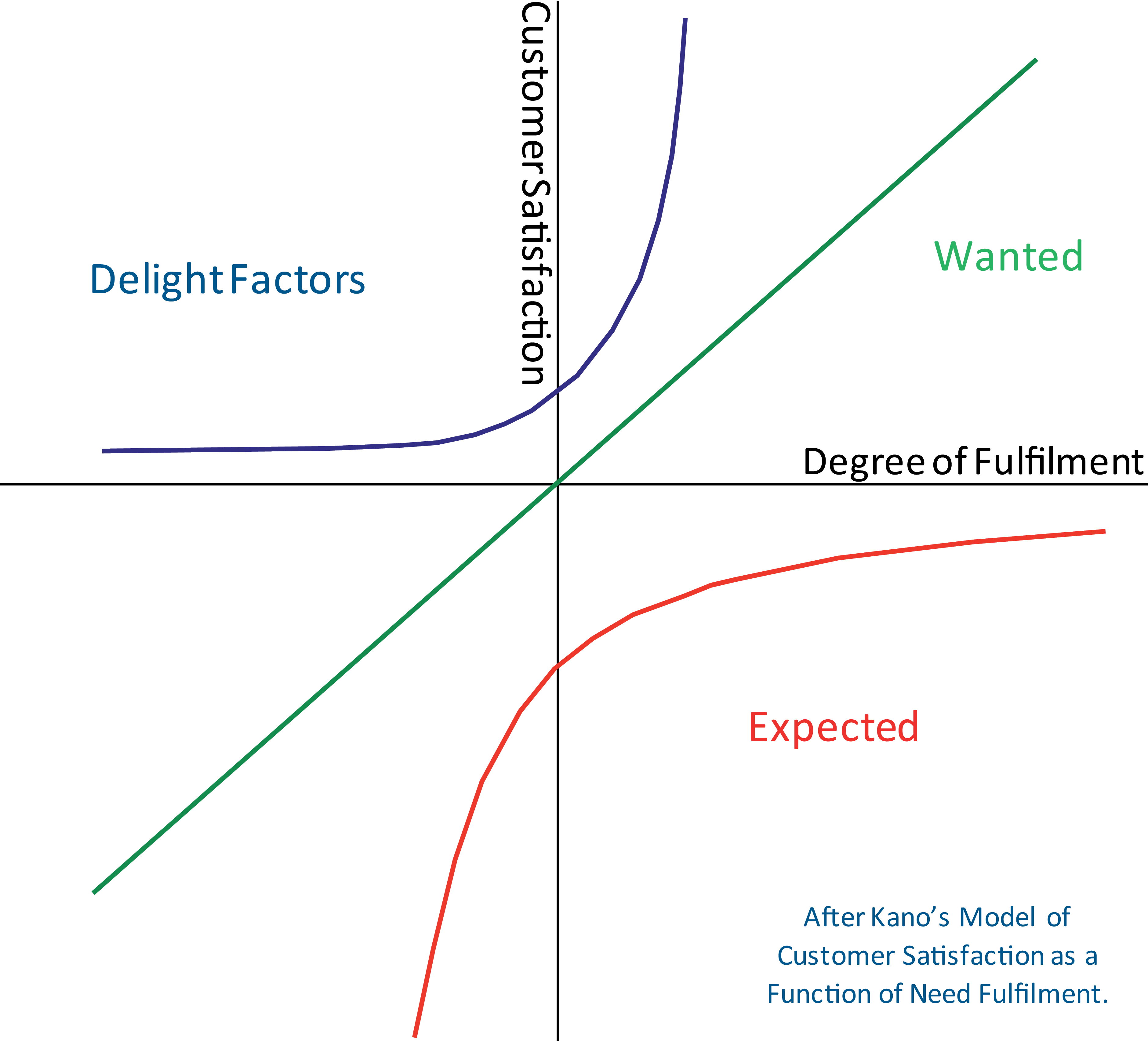

I’m certain that whoever designed this desk was talented; now it’s finally up I’m really pleased with it in terms of both appearance and function. The manufacturer is obviously technically capable since all the parts did go together in the end. But they forgot one crucial aspect – customer experience. I don’t think this retailer had an eye on its customer; they don’t seem to have envisaged how I would feel on receiving my box of panels, screws and hard-to-follow instructions. I might hesitate before buying one of their products again.

To order Implementing ISO 9001:2015 by Jan Gillett, Paul Simpson and Susannah Clarke from Infinite Ideas, please email info@infideas.com